Volumetric-measuring and continuous-mixing concrete equipment (VMCM)

Generic schematic of chassis cab mounted volumetric mixer showing component layout.

Generic schematic of chassis cab mounted volumetric mixer showing material flows.

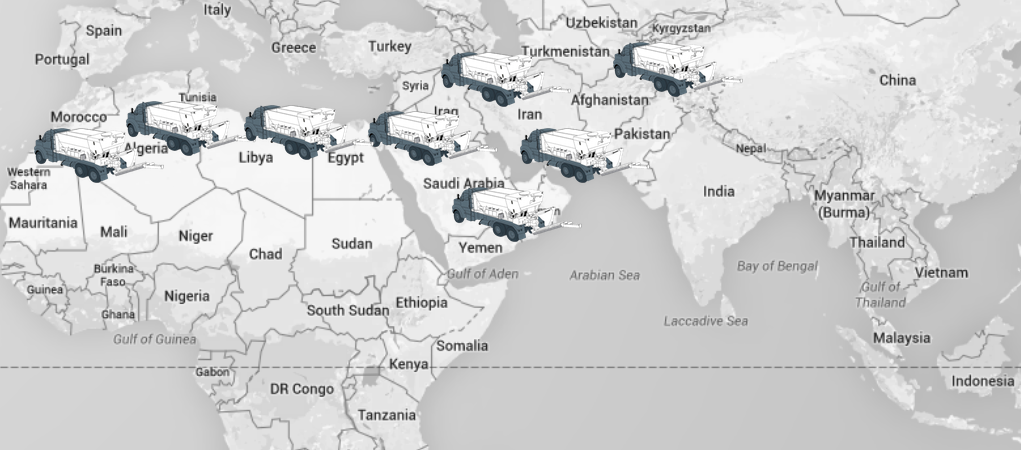

Volucon's equipment is best in class and has been optimised for the harsh MENA and Gulf climate. It is designed to offer continuous mixing of concrete, and our individual units can produce over 1,000 cubic meters of concrete per day. They are available to purchase and/or lease, in addition to Volucon advising and managing a concrete supply operation for our strategic partners.

Volucon's mixers are supported with training, parts and maintenance. This ensures maximum value for money for our customers and guarantees the shortest possible supply chain.

The VMCM unit can be mounted on a self-drive chassis, trailer unit, ocean going barge or even railway carriage, offering a wide range of delivery solutions.

The mobile mixer can be located onsite quickly and make fresh concrete to almost any design specification, at the point of need, and to international quality standards.

Quality, approvals and certification

Volumetrically measured and continuously produced concrete complies with all internationally recognised standards and can be specified to extremely fine tolerances (+/- 1% materials).

Each Volucon unit can produce more than 1,000 cubic meters of fresh concrete per day (requires reloading with a cycle time of less than 10 minutes, or the units can be continuously refilled to give non-stop production for complex pours e.g. deep foundation tremie pours).

By mixing the concrete freshly, where it is needed, to internationally recognised standards, new opportunities present themselves.

For example, ultra rapid hardening (URH) concrete (ASTM C1600) which provides rapid hardening, low shrinkage and is sulphate and chemical resistant – reaching structural strength in less than one hour (22MPa compressive strength) – can be produced easily from a Volucon VMCM unit.

Another major area of application, road and airport runway pavements, can be repaired and returned to service quickly, avoiding costly delays and interruptions to service.

Alternatively, URH cement can be used to pour key aspects of projects to avoid curing time delays, thus allowing work to continue, saving time and money.

Other examples and typical applications include:

- Natural pozzolans, fly ash, micro-silica, GGBFS etc blending using our dual bin units

- Fibre concretes: replacing the requirement to use costly rebar, can be produced to save time and project costs

- Marine and subsea concretes: produced fresh from units mounted on ocean going barges

- Polymer concretes, for bridge decks, dams, swimming pools etc. to provide low permeability to water and chemical resistance

- Coloured concretes can easily be produced to provide aesthetically pleasing results

- Fluorescent aggregate can be utilised to provide self-illuminating surfaces and demarcation paths

- Chemically resistant concrete that is thermally stable

- Shotcrete and gunite: specially adapted units can be used in underground mining and tunnelling operations and even for lining sewage drains using URH concrete because of its chemical resistance and long life