Khobar, Kingdom of Saudi Arabia, 29 January 2019. Al-Kifah Construction Equipment (KICE) and Volucon sign milestone agreement.

Volucon and Al-Kifah Construction Equipment (KICE) sign milestone agreement.

The agreement focuses on the distribution of Volucon’s unique mobile volumetric measuring and continuous mixing concrete production equipment, research and development and collaboration on green concrete.

In signing the deal KICE is aiming to lead the market in construction equipment by investing in the best technology as part of its strategic plan towards supporting the Kingdom’s 2030 Vision.

Volucon has developed the unit in partnership with Saudi Aramco, an investor in Volucon, to further Aramco’s green concrete agenda and provide access to Aramco specification concrete in remote locations.

Volucon’s Gulf specification mixers include advanced cooling technology to allow the units to operate without issue in the harsh Gulf climate and a unique dual bin technology that allows two cementitious materials to be independently blended to produce green concrete and a wide range of design mixes.

In line with the Kingdom’s Vision 2030 and Saudi Aramco’s In-Kingdom Total Value Add (IKTVA) Program, both companies are aiming to further localize the product line to drive additional domestic value creation to support a rapidly changing economic environment and foster future prosperity.

The Volucon story...so far

White Paper

Saudi Aramco introduces new concrete technologies to the master gas system pipeline project to address concrete supply and quality issues

Press release – Tuesday, 8th May 2018

Saudi Aramco introduces new Volucon concrete technologies to Master Gas System pipeline project.

Saudi Aramco introduces new concrete technologies to their Master Gas System pipeline project

– The Arabian Sun (Saudi Aramco Magazine)

Volucon's constructive solutions

Supplementary cementitious materials for concrete

Abstract

A wide variety of materials are currently used as a supplementary cementitious materials (SCMs) for concrete in the in the GCC & MENA regions, including natural materials and byproducts from various industries. Historically, natural SCMs, mostly derived from volcanic deposits, were common in concrete. In recent years, the dominant SCMs have been industrial byproducts such as fly ash, ground granulated blast furnace slag (GGBFS), and silica fume/microsilica, in addition to some natural pozzolans. There is currently a resurgence of research into historic and natural SCMs, as well as other alternative SCMs for many reasons. The primary benefits of SCM use in improvement of long-term mechanical performance, durability, and sustainability are widely accepted.

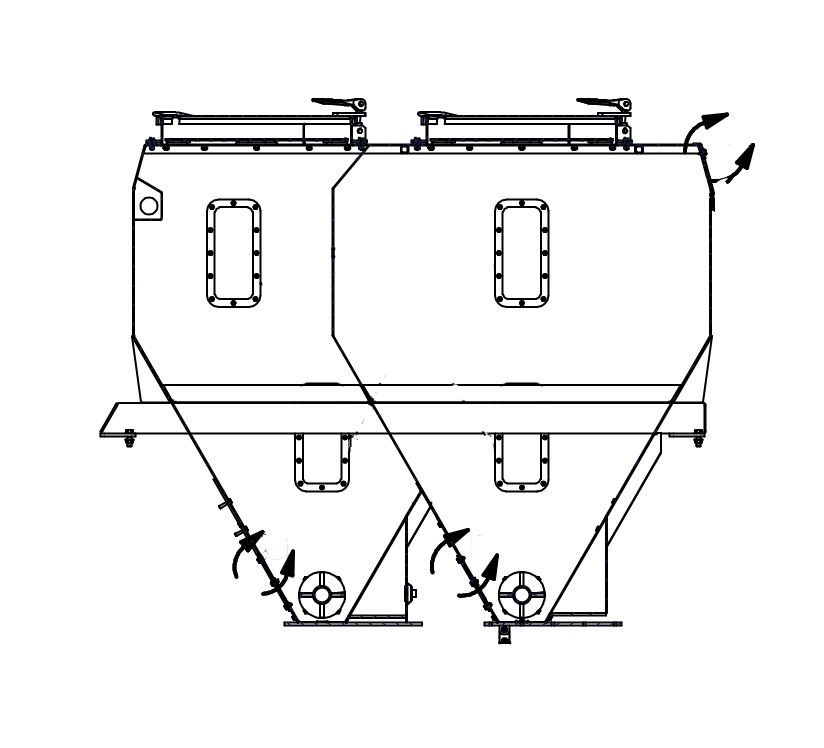

Schematic of Volucon's individually metered and computer controlled dual bin option.

Volucon’s Constructive Solutions

During the past two years Volucon has been focused on development work to ensure its volumetric mixers are truly best in class and support the GCC and MENA construction communities who are specifically focused on complying with the regions’ special requirements and concrete specifications (e.g. Saudi Aramco concrete specifications and the Dubai Municipality's green building rating system, “Al Safat”). These include, but are not limited to, the use of several supplementary cementitious blends with products such as GGBFS, fly ash, microsilica and natural pozzolans.

Volucon has introduced a special dual cementitious bin volumetric mixer configuration which can be mounted on a chassis cab, trailer, ocean barge or railway car platform, and can mix blends of cementitious products precisely with a superior accuracy as per the clients’ standards and specifications. These new Volucon mixers are a game changer in the region and unlock endless possibilities for the construction and industrial sectors as well as saving on capex and opex budgets.

Volucon addresses the Arabian Venture Forum 19-21 November 2016

Volucon's co-founder, Eng. Jamil Y Shinawi, addresses the Arabian Venture Forum's 19-21 November 2016 meeting at KAUST in the Kingdom of Saudi Arabia.

Volucon's was presented as a Saudi Aramco investee company, created to address a series of regional unmet needs. Specializing in producing specialty concretes with a unique delivery model, Volucon can produce concrete anywhere, independent of geography, to the highest international standards.

By combining regional exclusivity to the best volumetric-measuring and continuous-mixing concrete equipment, specialist cements and admixture components, Volucon can provide faster and more economic construction of key infrastructure projects, including the strategically important oil & gas, renewables, paving and defense sectors.

The ability to offer engineers structural strength concrete in hours opens up hitherto unthinkable possibilities, unlocking financial and logistical savings in small, medium and large scale projects.

Volucon units can be quickly deployed on land, rail or sea to deliver an almost unlimited number of unique concrete design mixes with lower capex and opex costs, in addition to being waste free and environmentally more robust than the traditional and less flexible models of concrete supply.

Building a 25 storey tower...in their own words.

For father-and-son team Yoram and Sholem Cimet—the designers and developers of the 25-storey Torre Glorieta office building in the heart of the city’s downtown core—there was no shortage of challenges ensuring their building was earthquake-proof. Traditional batch plants could not supply concrete fresh enough to meet Mexico City’s stringent regulations. In engineering terms, the concrete used in the columns must have a suitable modulus of elasticity—the flexible property of a material being able to absorb impact energy and return to its original size and shape.

Sourcing concrete of such high specifications in the very center of Mexico City, the largest metropolitan area in the western hemisphere, was a massive challenge. Sholem explains: “in our investigation we were told that it is difficult to obtain that elastic modulus due to the travel time of the trucks from the plant to the building site, because much of the time these mixer trucks get stuck in traffic under hot conditions.”

In the end, no supplier or contractor made offers on the job, as none could assure that concrete could be supplied within the city’s tight standards. When Yoram and Sholem went looking for a solution, they found a perfect fit with VMCM mixers, purchasing a mobile mixer and supplying their own concrete on site. One mixer allowed the crew to take total control of their delivery logistics, and eliminated the possibility of a poor mix design by only mixing the concrete materials when needed. “To have the volumetric mixer here at the construction site has allowed us to reach those elastic modulus values”, says Tapia, “in other places it is not possible because the concrete, from the moment it is mixed to the time when it is put in its place, it can be up to 3 hours of time.”

To ensure all specifications were being met, an on-site lab performed over 800 tests throughout the construction process, testing the concrete for elasticity, dimensional weight, and resistance. There wasn’t a single failed test.

A fascinating insight into how major airports are maintained and kept operational the Volucon way.

Press release – Thursday 31st December, 2015

Saudi Aramco Entrepreneurship Ventures Co. Ltd Invests in Volumetric Concrete (Volucon)

Saudi Aramco Entrepreneurship Ventures Co. Ltd., a $200,000,000 fund with Saudi Aramco as its sole shareholder, has made an investment into Volucon Est. with an approved intention to inject further capital (c. 18,750,000 SAR) into the company as part of a syndicated round with other investors. Saudi Aramco is the Saudi Government owned national oil company.